SB Specialty Metals in the News -8/27/2020

09/03/2020

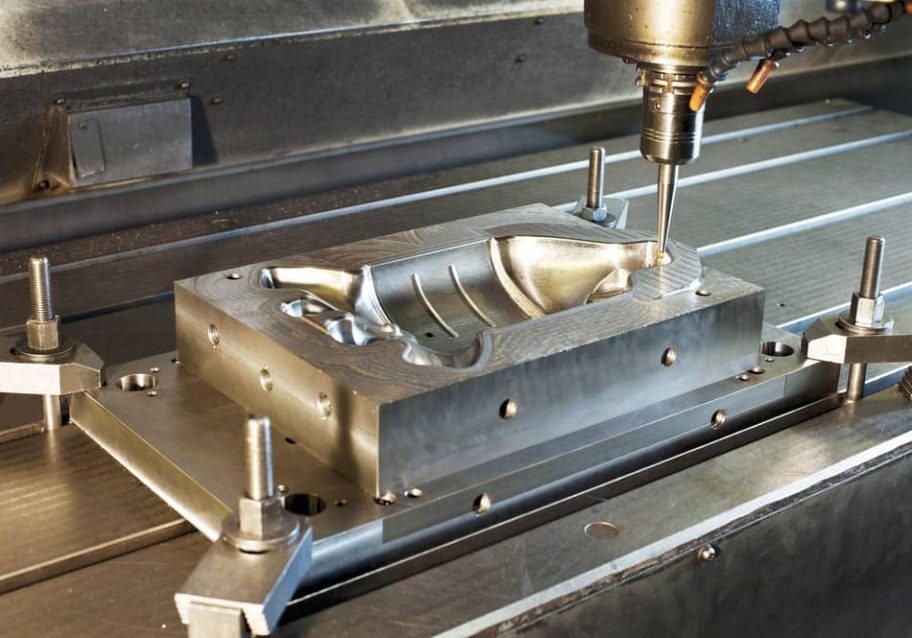

SB Specialty Metals, LLC is in Metal Center News for introducing a unique line of tool steels to the marketplace. These unique tool steels are produced using the Spray Forming process.

- This technology has been tested and the equipment has been developed and built and is now producing product.

- SB Specialty Metals, LLC is developing an entire line of products based on this process and will offer a cost competitive option in the particle metallurgy marketplace.

- Spray formed tool steels will be competitively positioned in the market, allowing customers to choose the right tool steel at the right price for their applications.

The first product in this line to hit the market is PSB27, which has properties that are between D2 & PMM4 with a price closer to the D2. This provides a cost advantage while creating a long-lasting tool with a lower total cost of ownership for the right application.

Spray forming is a method for producing premium particle metallurgy tool steel ingots. The ingots are then forged and rolled into round bars or plates. The spray forming process produces a structure that results in improved wear resistance, toughness and chip resistance compared to conventionally produced tool steels. Also, spray formed tool steels have larger, spherical carbides than HIP’d powdered metal tool steels. This imparts improved wear resistance while still maintaining toughness.