Particle Metallurgy Grades

The Particle Metallurgy Steel grades below are generally available from stock.

The technical data sheets for each grade are available for download.

PD#1

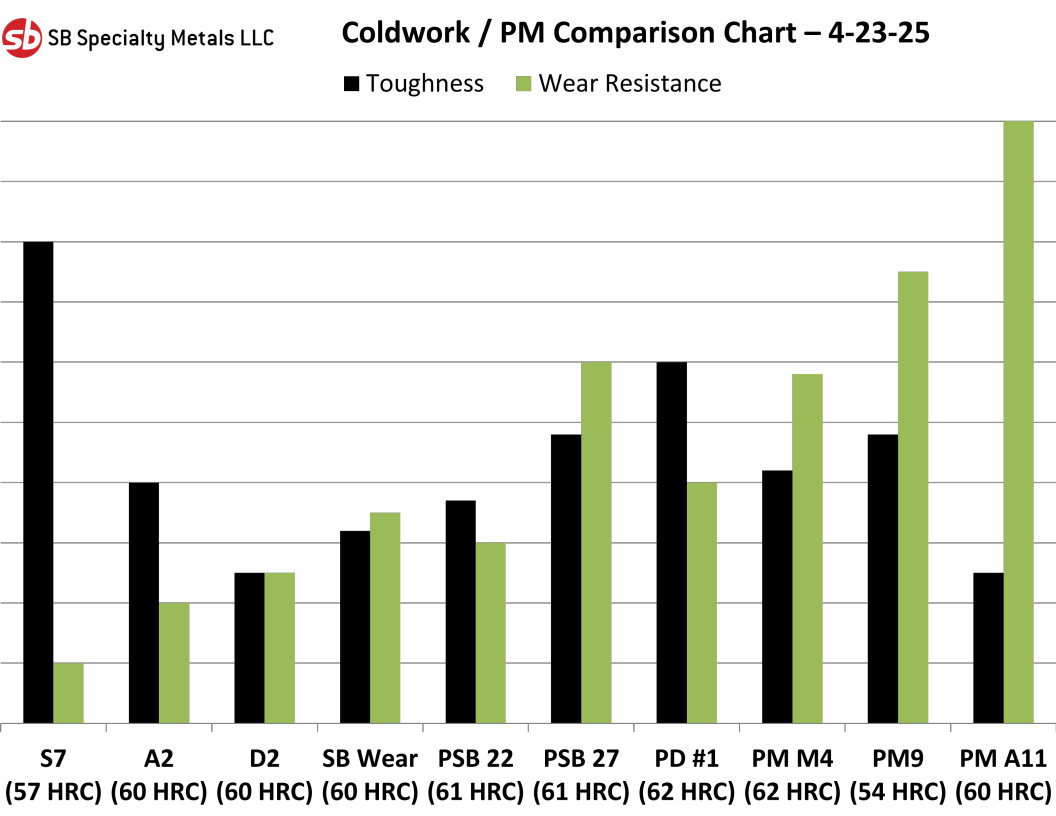

PD#1 is an air hardening cold work tool steel having excellent wear resistance and toughness.

Available in the following sizes:

- Rounds: 1.015" dia. through 7.125" dia.

- Flats: 0.187" through 4.03" thick

PM 9

PM9 has excellent wear resistance with excellent toughness, making it well suited for many cold work tooling applications.

Available in the following sizes:

- Rounds: 1.00" dia. through 4.562" dia.

- Flats: 0.500" through 3.000" thick.

PM A11

PM A11 has excellent wear resistance with very good toughness and strength making it well suited for many cold work tooling applications.

Available in the following sizes:

- Rounds: 0.375" dia. through 12" dia.

- Flats: 0.056" through 8.000" thick

PM420

PM420 is a particle metallurgy, high vanadium corrosion resistant tool steel.

Available in the following sizes:

- Rounds: 0.625" dia. through 5.5625" dia.

- Flats: 1.03" through 12" thick.

- Saw cut widths up to 24"

PM M4

PM M4 is a special purpose high speed steel exhibiting better wear resistance than M2 or M3.

Available in the following sizes:

- Rounds: 0.198" dia. through 13.125" dia.

- Flats: 0.070" through 12.00" thick.

- Saw cut widths up to 24"

PM M48

PMM48 is a super high speed steel with abrasion resistance equal to T15 and superior red hardness to T15 and M42.

Available in the following sizes:

- Rounds: 0.25" dia through 1.765" dia.

- Flats: 0.500" through 2.500" thick.

- Saw cut widths up to 24".

PM T15

PMT15 is a high carbon-tungsten-cobalt-vanadium high speed steel made using the PM (powder metallurgy) process.

Available in the following sizes:

- Rounds: 0.325" dia. through 7.125" dia.

- Flats: 0.218" through 12" thick.

- Saw cut widths up to 24".

PM 32Co

PM32CO is a super high speed steel with 8% Cobalt.

PM32CO has excellent hot hardness along with good wear resistance and and toughness.

Available in the following sizes:

- Rounds: 0.765" dia. through 7.75" dia.